In the dynamic world of manufacturing, the constant evolution of technologies is pivotal. From the precision of CNC machining to the versatility of sheet metal fabrication, and the robustness of milling processes, modern manufacturing has a plethora of technologies at its disposal. This article provides an in-depth look at these key manufacturing technologies, discussing their advancements, applications, and future potential.

CNC Machining: Precision and Flexibility

Overview CNC (Computer Numerical Control) machining stands as a cornerstone of modern manufacturing. This process utilizes computerized controls to handle complex machinery, from lathes to mills, executing intricate designs with high precision.

Advancements Recent years have seen significant advancements in CNC technology, including enhanced software for more accurate tool path planning, multi-axis machines for complex shapes, and improved automation for higher productivity.

Materials and Applications CNC machining is versatile, handling a range of materials like aluminum, steel, titanium, and plastics. Its applications span aerospace for turbine parts, automotive for engine components, and medical for surgical tools.

Sheet Metal Fabrication: From Flexibility to Durability

Fundamentals Sheet metal fabrication involves cutting, bending, and assembling metal sheets. It’s a process used for creating everything from small brackets to large metal parts.

Innovations Technological innovations include high-precision laser cutters and CNC press brakes, allowing for more intricate designs and faster production times.

Applications This technology is widely used in automotive for body panels, construction for roofing materials, and in HVAC systems for ductwork.

Milling: Versatility in Material Removal

Milling: Versatility in Material RemovalBasics Milling, a process of using rotary cutters to remove material, is essential in manufacturing for creating a variety of parts.

Technological Growth Advancements in milling include the development of multi-axis machines and high-speed milling, allowing for more complex geometries and faster production.

Material Compatibility Milling is compatible with a wide array of materials, including metals, plastics, and composites, making it suitable for sectors like aerospace, automotive, and electronics.

Emerging Technologies in Manufacturing

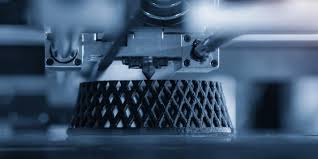

Additive Manufacturing (3D Printing) This process builds parts layer by layer, allowing for complex geometries and reduced material waste. It’s increasingly used in prototyping, custom parts, and even in medical implants.

Robotics and Automation Robotics in manufacturing enhance efficiency and precision. Automated assembly lines and robotic arms are becoming commonplace in high-volume production environments.

Smart Manufacturing Incorporating IoT and AI in manufacturing leads to smarter production processes. This includes predictive maintenance, real-time monitoring, and enhanced quality control.

Conclusion

The landscape of modern manufacturing is continually reshaped by technological advancements. From the precision of CNC machining, the flexibility of sheet metal fabrication, the robustness of milling, to the innovative realms of additive manufacturing and robotics, the industry is evolving rapidly. Understanding these technologies and their applications is essential for anyone involved in the manufacturing sector, as they hold the key to efficiency, quality, and innovation.